IA4ZERO_DEFECTS, the project that will revolutionize the quality of final parts by using artificial intelligence with 3D laser and 2D and 3D vision.

Scroll down

“Quality control of final parts using artificial intelligence with 3D laser and 2D and 3D vision for the automotive sector”.

🔝IA4ZERO_DEFECTS, the project that will revolutionize the quality of final parts by using artificial intelligence with 3D laser and 2D and 3D vision 📹

Its objective?🎯👀

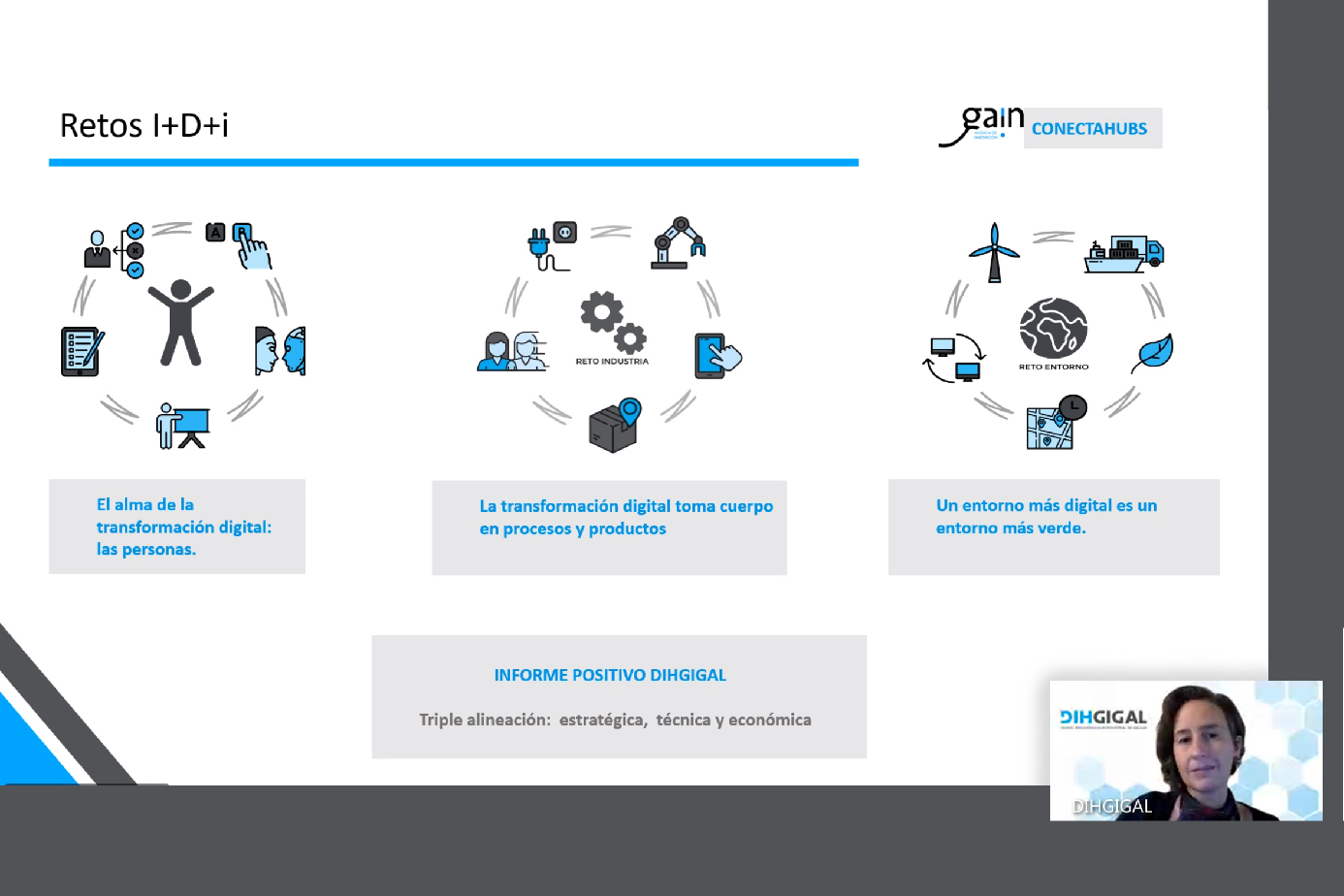

Achieve zero defects in shipped products, through the development of high precision systems that enable the automation of quality systems in the supply chain.

CEAGA – Automotive and Mobility Cluster of Galicia leads the consortium of which #DIHGIGAL is part, together with UNIMATE ROBOTICA, Logicmelt, Decuna S.L., Grupo Copo, INPLASOR GALICIA SL y TI Fluid Systems, in order to develop innovative and efficient solutions that contribute to the increase of Overall Equipment Effectiveness (OEE) 💻💡👨💼

Thanks to the analysis of different AI systems, the application of machine learning and Edge technology, greater precision will be achieved in the production process, avoiding non-conforming parts at an affordable cost💰💡👌.

I4ZERO_DEFECTS is the solution that ensures quality in the final part and success in the automotive sector!💪🏼💡

This project has a budget of 527,638.41 €💰 and is funded by the Ministry of Industry, Trade and Tourism, as well as by the EU through the Recovery, Transformation and Resilience Plan under the #AEI2022b call.

#IA4ZERO_DEFECTS #AutomotionGalicia #ArtificialIntelligence #Láser3D #Vision2D #Vision3D #Quality #ZeroDefects #Automation #OEE #EnergyEfficiency #Innovation #Industry #Projects

CURRENT NEWS

Related news